Our story

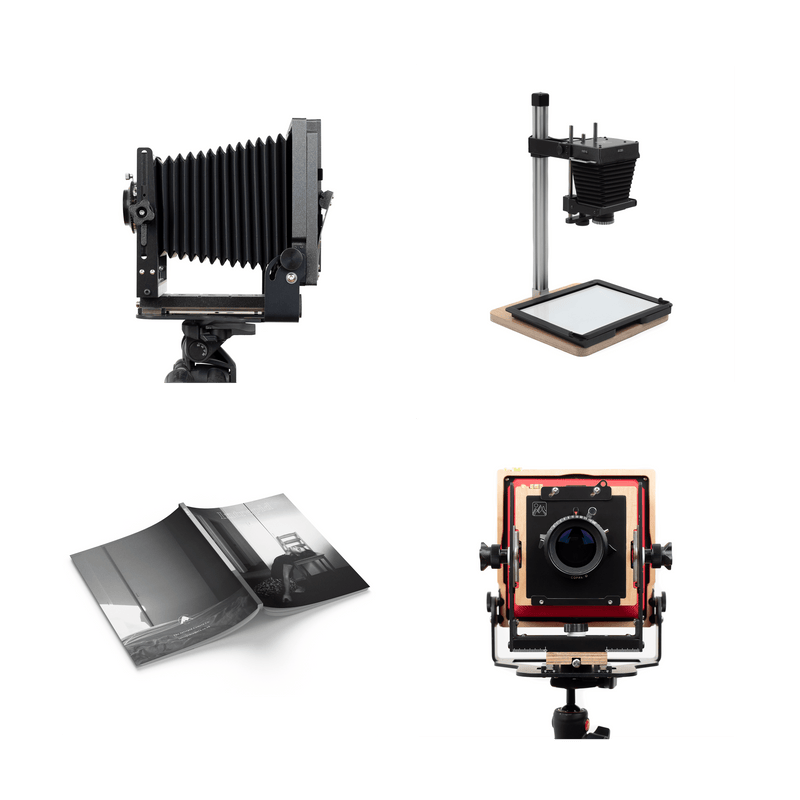

Intrepid Camera started life back in 2014 with the idea of an affordable and lightweight 4x5 camera.

We wanted to make large format photography accessible to a much wider audience and have successfully been doing so for over seven years.

Nothing compares to composing an image on the ground glass, and prints made from the giant negatives have a quality and depth to them that is like nothing else. We are now the biggest modern manufacturers of large format film cameras worldwide and offer a full range of 4x5, 5x7 and 8x10 cameras plus an extensive selection of innovative accessories.

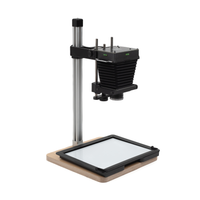

Our next challenge was darkroom printing and in 2018 we launched our first 4x5 Enlarger. We then developed the Compact Enlarger in 2021, marking our expansion into the vast world of 35mm and 120 film.

Intrepid Enlargers are a fraction of the size of traditional enlargers whilst matching the results. They use new LED technology which allows you to print from colour and black and white film, all without needing a dedicated darkroom. While scanning your film is rewarding nothing quite beats the joy of making darkroom prints.